An Urgent Need for Innovation in Asbestos Risk Management

The asbestos monitoring industry faces a critical labor shortage and increased workload due to stricter regulations. This strain is exacerbated by the demanding, meticulous nature of manual fiber counting for asbestos air monitoring, with past automation attempts like Magiscan and Asbestos Alert failing to displace the regulatory method of manual fibre counting.

A modern AI-powered platform, Marvin, offers a proven, automated approach. By combining robotics and AI with standard phase contrast microscopy, Marvin can analyze significantly more samples than a human analyst with high accuracy. This technology addresses the coming analyst shortage, ensures consistent and accurate results, and future-proofs the industry. The company is now seeking strategic partners to achieve regulatory approval for wider adoption.

Applying AI to Solve Imminent Skill Shortages in Asbestos Management

For decades, the meticulous work of analysts counting asbestos fibers under the microscope to quantify airborne asbestos has been a cornerstone of safe asbestos management. However, this essential task is physically and mentally demanding, and retaining skilled staff is harder than ever.

This problem is set to worsen as planned updates to sensitivity requirements will require analysts to examine more of each sample, almost doubling workload and pushing an already strained workforce to a breaking point. For example, the European Parliament plans to lower the occupational exposure limit for asbestos fibers in the air from 0.1 to 0.01 f/ml. This stricter standard will increase the burden on analysts, requiring them to analyze more fields of view on each sample to meet the lower limit.

The Need for Innovation

The current reliance on manual analysis, while effective, presents several challenges that threaten the industry’s ability to keep pace with modern standards. A new approach is necessary to address the escalating analyst shortage, the inherent limitations of human analysis, and the increasing burden of stricter regulations. By embracing automation, the industry can enhance data quality, improve efficiency, and ultimately create a more robust system for protecting public health.

The Battlefield of Unrealized Technologies

Over the years, several technologies have attempted to automate asbestos fiber counting but have failed to deliver a viable, long-term solution. Key examples include Magiscan and Asbestos Alert.

Magiscan: Developed in the 1980s, Magiscan was an image analysis system that aimed to automate fiber counting. While it showed promise in research and quality control settings, it struggled with the reduced control limits and the increased number of clearance indicator and background samples, where concentrations <0.01 f/ml were required to be assessed as well as other real-world complexities.

Asbestos Alert: Emerging more recently, the ALERT PRO 1000 promised real-time airborne asbestos fibre monitoring using light scattering, and the paramagnetic properties of asbestos fibres. Its recent failure may have been due to a combination of technological limitations, industry skepticism and reluctance to adopt real-time monitoring inside removal enclosures, or an inability to produce data comparable to traditional asbestos fiber counting results.

These innovations promised great strides for improving asbestos monitoring but failed to manage the nuances and inconsistencies found in real-world samples and, most importantly, produce data that is relevant, trusted, and reliable.

Introducing Automated Fibre Counting with Marvin

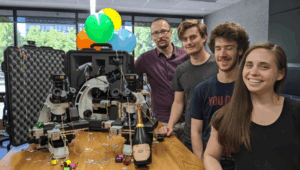

Marvin is an AI-powered platform for automated PCM asbestos fiber counting, developed by Marvin Labs (formerly Frontier Microscopy) in close collaboration with commercial laboratories and industry leaders, including Dr. Martin Harper, former senior scientist with CDC-NIOSH and co-author of the most recent NIOSH 7400 method for asbestos fiber counting.

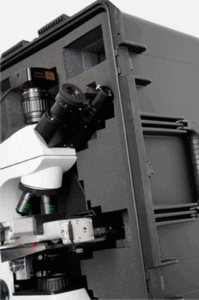

The Marvin system achieves automation by combining standard phase-contrast microscopy (PCM) with modern robotics and AI. Whilst restrictions on analysts will limit them to examining no more than 12 samples per day, Marvin does not fatigue and thus can analyse 100+ samples per day. Marvin can also be operated with minimal training, thus minimizing the skill attrition that manual analysis suffers from.

The Marvin analysis process closely follows existing PCM standard for asbestos fiber counting through a streamlined three-step workflow:

- Macro Assessment: An AI uses a macro camera to capture an image of the prepared microscope slide sample, map the features for scanning, and assess the sample’s quality.

- Micro Scanning: The system performs a point scan for fiber counting, capturing a vertical stack of images across the entire sample depth.

- Fiber Counting: The AI software then analyzes these images to count and classify fibers, capable of accurately separating particles from artifacts and differentiating overlapping fibers.

Through automation, Marvin aims to address the industry’s most pressing challenges:

- Analyst Shortage: By automating the painstaking counting process, Marvin frees the abatement process from relying on the bottleneck of manual fibre counting.

- Quality and Consistency: The system eliminates human fatigue, applies counting rules consistently, and reduces the potential for human error, leading to more reliable and accurate results.

- Future-Proofing the Industry: Marvin’s efficiency allows laboratories to handle increased sample volumes and stricter analysis requirements without a proportional increase in labor.

From Concept to Reality: A Strategic Roadmap

Marvin is a robust commercial solution that has been piloted on projects across Europe, the US, and Australia. Development of the technology required significant investment of over a million US dollars across five years to support a world-class team of AI researchers, software engineers, and industrial designers. This investment has translated into tangible outcomes:

- Proven Technology: The team has successfully developed and tested commercial-grade robotic microscope hardware and its AI software, ensuring high-quality and accurate performance.

- Scalable Production: With 30 units in existing inventory, the company has the skills and capacity to produce additional units.

Marvin’s commercial strategy is centered on achieving acceptance for its WK83115 standard within the ASTM International, which is critical for industry-wide adoption. The standard acts as a “wrapper” for existing regional methods and was authored in collaboration with Dr. Martin Harper, and International Asbestos Testing Laboratories (IATL).

The project is close to completion. The initial draft is nearing vote with the final remaining step to complete a single-user study for the precision and accuracy statement and then submit the final draft for a sub-committee ballot.

Unlike prior attempts at innovation, this Marvin system is designed to automate the existing standard, thus maintaining the important connection to historical analytical data linking airborne asbestos exposure to impacts on human health.

The Broader Impact: A Shift in Industry Mindset

The industry is beginning to understand the need to support innovation from within as investment in forward-looking technology is now seen as a strategic necessity. Eurofins, one such major international player, has already embraced AI-driven automation for TEM asbestos analysis, signaling a powerful shift. For smaller and medium-sized businesses, new models of collaboration and resource sharing will be key to remaining competitive.

A New Chapter for Asbestos Analysis

The need for automation in the asbestos risk management industry is urgent, and the Marvin system offers a proven, reliable path forward. This isn’t just about a new product; it’s about addressing the need to address coming skill shortages.

To make this vision a reality and bring this transformative technology to market, we are actively seeking partners to achieve regulatory acceptance for Marvin through pre-ordering or strategic investment. Forward-thinking industry leaders ready to join our mission are welcome to contact us at jordan@marvinlabs.ai